Warehouse Racking Inspection Checklist Pdf

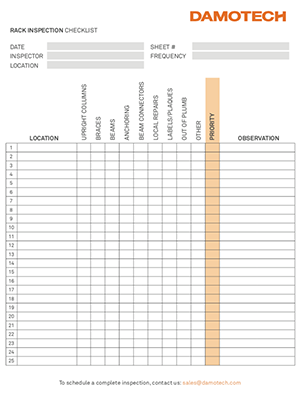

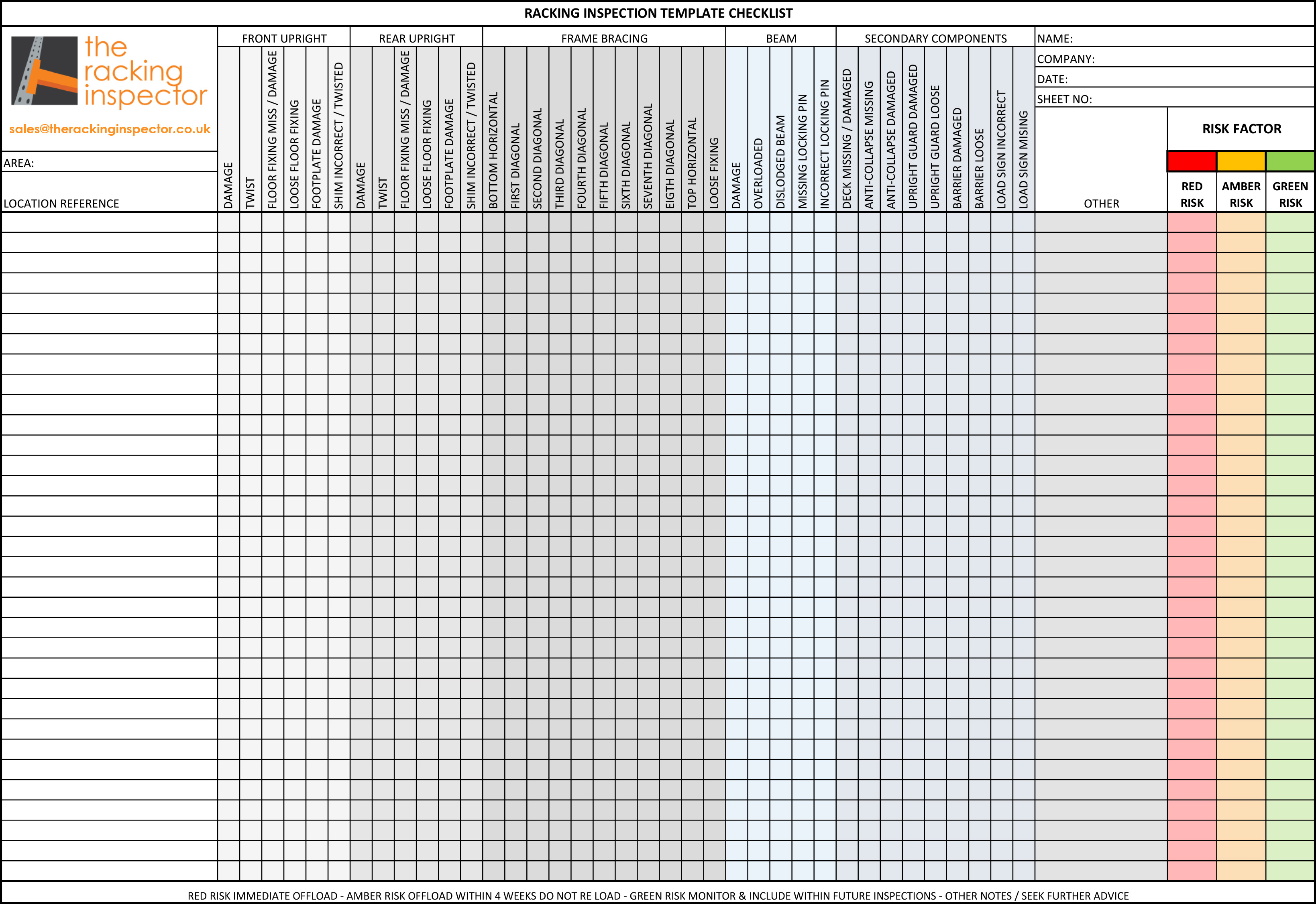

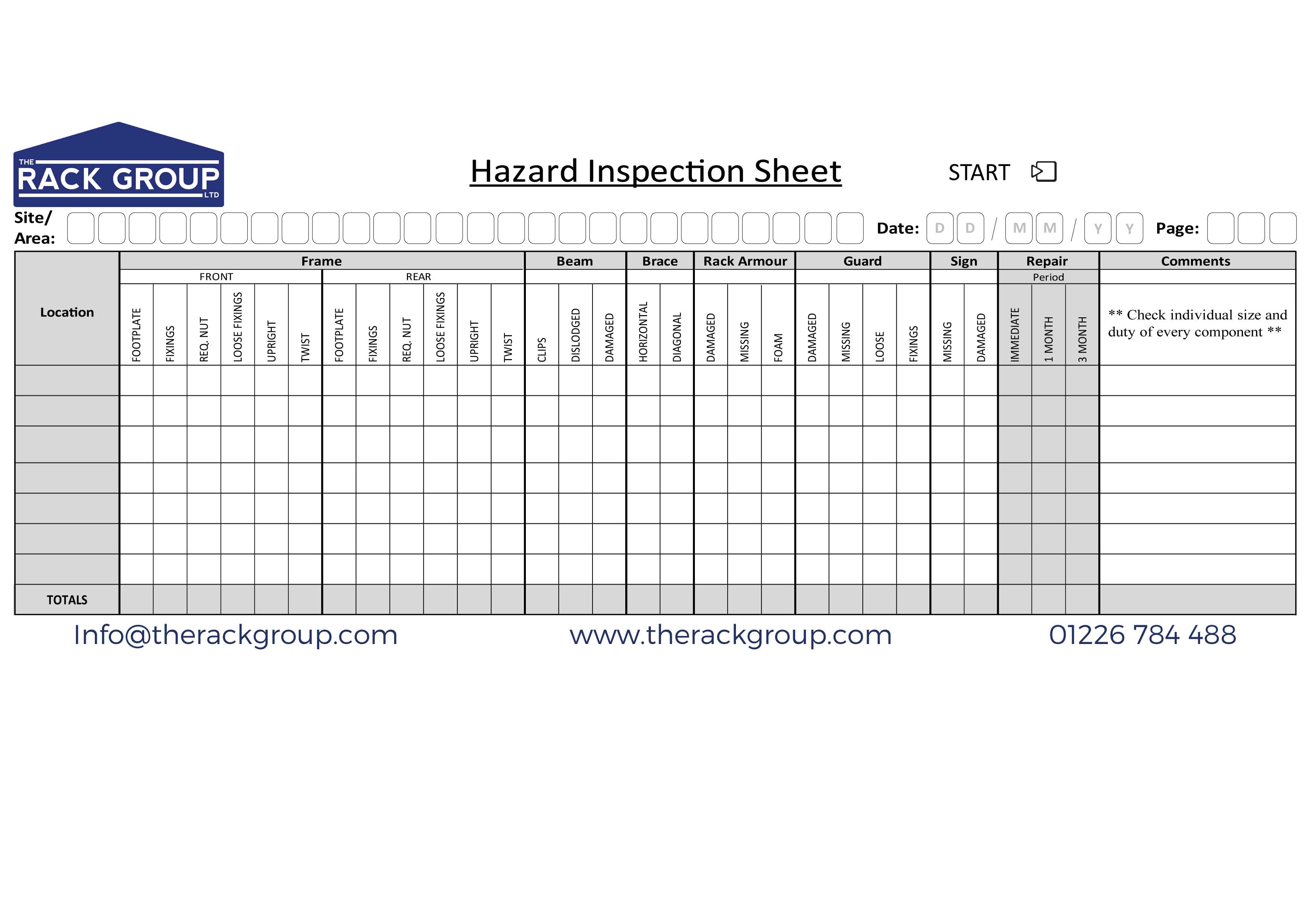

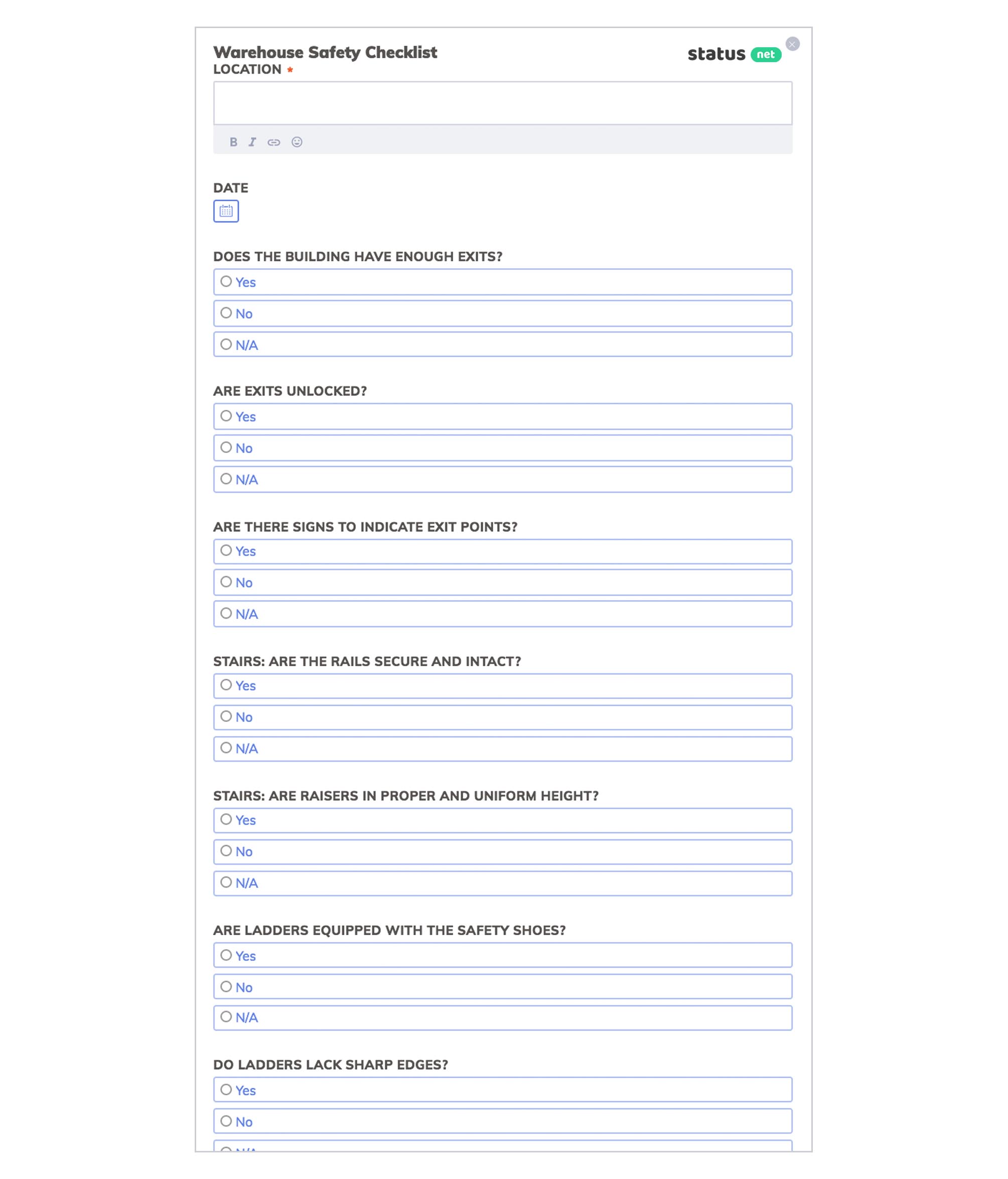

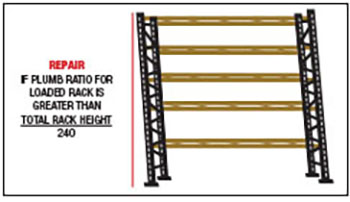

A racking inspection checklist is used by authorized warehouse inspectors to identify rack issues or any potential risks of a rack collapsing this tool can be used to assess rack components such as frames beams and braces and determine the level of risks through the traffic light system.

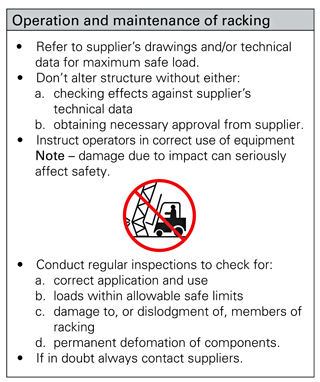

Warehouse racking inspection checklist pdf. Our inspection checklist can be used for frequent internal inspections by your prrs. Ensure your workplace is compliant with osha regulations and your workforce is kept as safe as possible by reviewing your racking and storage practices regularly. The racking inspector carried out an annual inspection on our warehouse racking system and was very knowledgeable very helpful and informative with useful tips to help us maintain a. Racking inspection checklist sema use an efficient and informative traffic light system to identify all types of damage red immediate offload amber do not reload after 4 weeks upgrade to red green continue to monitor.

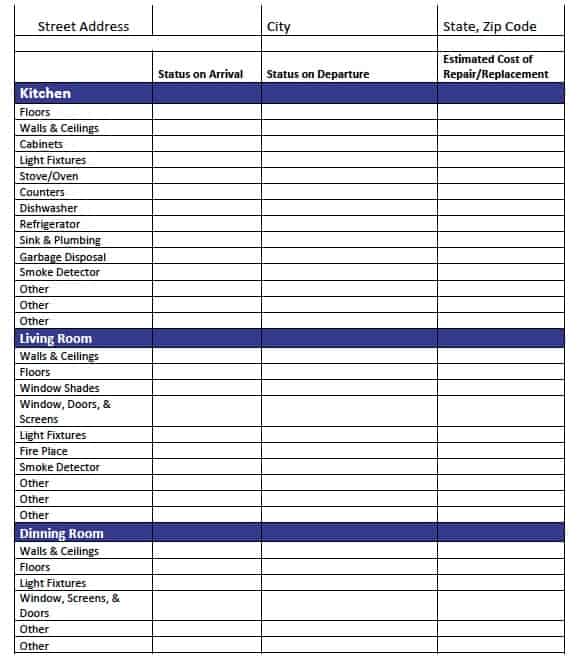

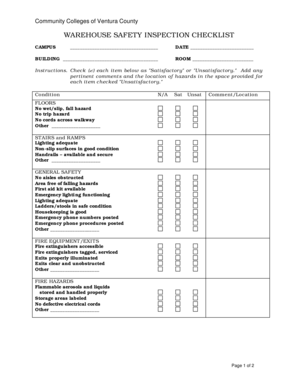

Download our free rack inspection checklist in both excel pdf formats. Check each item below as satisfactory or unsatisfactory add any pertinent comments and the location of hazards in the space provided for. Warehouse racking and storage checklist warehouses conditions can expose workers to numerous hazards including bodily strain and falling objects.